Mô tả sản phẩm:

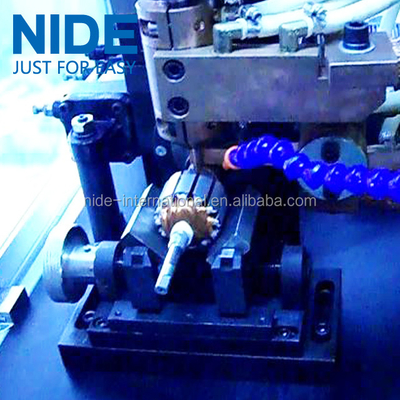

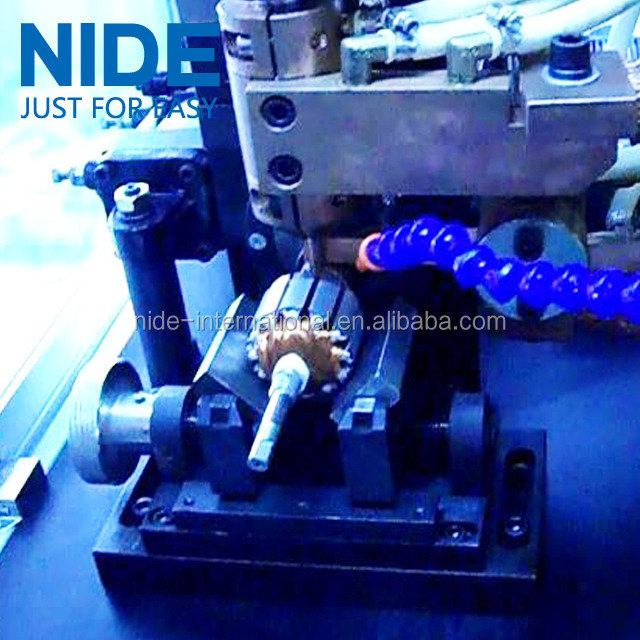

Chào mừng bạn đến với tóm tắt sản phẩm của chúng tôi cho Máy cuộn dây, một máy cuộn dây tiên tiến được thiết kế cho các hoạt động cuộn dây hiệu quả và chính xác.Máy hiện đại này tự hào một loại tự động hoàn toàn, làm cho nó trở thành sự lựa chọn hàng đầu cho các nhà sản xuất tìm kiếm các quy trình sản xuất hợp lý.

Máy cuộn Armature có 2 trạm làm việc, cung cấp tính linh hoạt và tăng khả năng xử lý nhiều nhiệm vụ cuộn đồng thời.Điều này cho phép tăng năng suất và giảm thời gian sản xuất, làm cho nó trở thành sự lựa chọn lý tưởng cho môi trường sản xuất khối lượng lớn.

Được thiết kế đặc biệt cho việc cuộn các động cơ máy hút bụi, máy này cung cấp hiệu suất và độ chính xác vô song trong các ứng dụng cuộn armature.Công nghệ tiên tiến và kỹ thuật chính xác đảm bảo kết quả cuộn liên tục và đáng tin cậy, đáp ứng các yêu cầu nghiêm ngặt của ngành.

Kích thước gói của máy cuộn dây là 1000.00cm * 800.00cm * 800.00cm, cung cấp một giải pháp nhỏ gọn nhưng mạnh mẽ cho nhu cầu cuộn của bạn.Thiết kế tiết kiệm không gian này làm cho nó dễ dàng để tích hợp vào dây chuyền sản xuất hiện tại của bạn trong khi tối đa hóa hiệu quả và dòng chảy công việc.

Được trang bị phương pháp điều khiển động cơ servo Lap Winding 3, máy cuộn dây này mang lại sự kiểm soát và chính xác đặc biệt trong quá trình cuộn.Công nghệ động cơ servo đảm bảo hoạt động cuộn trơn tru và chính xác, kết quả là các thiết bị gắn kết chất lượng cao đáp ứng các tiêu chuẩn hiệu suất và độ tin cậy nghiêm ngặt nhất.

Là một trong những nhà cung cấp máy bọc thép hàng đầu, chúng tôi tự hào cung cấp các giải pháp tiên tiến đáp ứng nhu cầu phát triển của ngành công nghiệp.Máy cuộn dây của chúng tôi kết hợp đổi mới, hiệu quả và độ tin cậy để cung cấp kết quả vượt trội và tăng cường khả năng sản xuất của bạn.

Cho dù bạn là một hoạt động quy mô nhỏ hoặc một cơ sở công nghiệp lớn, Máy lắp dây chuyền là sự lựa chọn hoàn hảo để đạt được kết quả lắp dây chuyền phù hợp và chất lượng cao.Đầu tư vào máy tiên tiến này ngay hôm nay và trải nghiệm sự khác biệt trong hiệu quả sản xuất và sản lượng của bạn.

Đặc điểm:

- Tên sản phẩm: Máy cuộn dây cáp

- Thích hợp cho: Động cơ máy hút bụi

- Địa điểm làm việc: 2

- Động cơ chỉ mục: MITSUBISHI-750W

- Loại tự động hóa: Tự động hoàn toàn

- Phương pháp điều khiển: Lốp cuộn 3 Servo Motor

Các thông số kỹ thuật:

| Com Bars |

12 Bar, 24 Bar, 36 Bar |

| Loại tự động hóa |

Hoàn toàn tự động |

| Kích thước gói |

1000.00cm * 800.00cm * 800.00cm |

| Số khe quay rotor |

Thậm chí Slots |

| Căng thẳng |

Điều chỉnh |

| Địa điểm làm việc |

2 |

| Động cơ chỉ mục |

Mitsubishi-750W |

| Phương pháp điều khiển |

Động cơ servo 3 vòng xoắn |

| Chiều kính giáp |

22 - 80 mm |

| Chiều dài lõi |

10 - 130 mm |

Ứng dụng:

Máy cuộn dây, một máy cuộn dây là một thiết bị linh hoạt và thiết yếu phù hợp với các ứng dụng và kịch bản khác nhau.máy cuộn dây tự động này từ Trung Quốc được thiết kế để đáp ứng một loạt các yêu cầu trong ngành công nghiệp điện.

Sản phẩm này là lý tưởng cho các doanh nghiệp và xưởng làm việc đòi hỏi các quy trình cuộn dây cáp hiệu quả và chính xác.làm cho nó trở thành một tài sản có giá trị cho các nhà sản xuất sản xuất vòm trong phạm vi đường kính 22-80 mm.

Được chứng nhận với CE, máy cuộn dây này đảm bảo tuân thủ các tiêu chuẩn quốc tế, cung cấp độ tin cậy và đảm bảo chất lượng cho người dùng.Số lượng đặt hàng tối thiểu 1 bộ làm cho nó có thể truy cập được cho cả các hoạt động quy mô nhỏ và các doanh nghiệp lớn hơn muốn tăng khả năng sản xuất của họ.

Giá cả và thời gian giao hàng có thể đàm phán mang lại sự linh hoạt cho khách hàng, cho phép họ đàm phán các điều khoản phù hợp với nhu cầu cụ thể của họ.chi tiết bao bì trong một vỏ gỗ đảm bảo vận chuyển an toàn, đặc biệt là cho các chuyến hàng biển, thêm sự tiện lợi cho quá trình mua hàng.

Với công suất năng lượng 2,5kW và động cơ lập chỉ số từ MITSUBISHI với 750W, máy cuộn dây này cung cấp hiệu suất hiệu quả trong khi duy trì hiệu quả năng lượng.Mã HS 8479811000 tiếp tục tạo điều kiện thanh toán hải quan trơn tru cho người mua quốc tế.

Khả năng cung cấp 60 bộ mỗi năm đảm bảo sự sẵn có ổn định của sản phẩm trên thị trường, phục vụ nhu cầu ngày càng tăng về các giải pháp cuộn tự động trong các ngành công nghiệp khác nhau.Cho dù được sử dụng trong một nhà máy sản xuất quy mô lớn hoặc một xưởng chuyên dụng, Máy cuộn Armature chứng minh là một sự lựa chọn đáng tin cậy và hiệu quả về chi phí để nâng cao quy trình sản xuất.

Tùy chỉnh:

Dịch vụ tùy chỉnh sản phẩm cho máy cuộn dây:

Địa điểm xuất xứ: Trung Quốc

Chứng nhận: CE

Số lượng đặt hàng tối thiểu: 1 bộ

Giá: Có thể đàm phán

Chi tiết bao bì: Vỏ gỗ phù hợp để vận chuyển bằng đường biển

Thời gian giao hàng: Có thể đàm phán

Khả năng cung cấp: 60 bộ mỗi năm

Thích hợp cho: Động cơ máy hút bụi

Địa điểm làm việc: 2

Tự động: tự động

Chiều kính: 22 - 80 mm

Các trạm xoắn: 4

Hỗ trợ và Dịch vụ:

Sản phẩm Máy cuộn cáp của chúng tôi đi kèm với hỗ trợ kỹ thuật và dịch vụ sản phẩm toàn diện để đảm bảo hoạt động trơn tru và hiệu quả tối đa.Nhóm chuyên gia kỹ thuật chuyên nghiệp của chúng tôi có sẵn để hỗ trợ cài đặtNgoài ra, chúng tôi cung cấp các chương trình đào tạo để giúp các nhà điều hành tối ưu hóa hiệu suất của máy.Nhóm dịch vụ của chúng tôi cam kết cung cấp dịch vụ bảo trì và sửa chữa nhanh chóng để giảm thiểu thời gian ngừng hoạt động và giữ cho sản xuất của bạn hoạt động trơn tru.